Choosing your oil viscosity

It may feel like there are a million different oils out there, but steps can help manage the otherwise endless task, and make it approachable.

Our checklist offers quick tips on oil selection

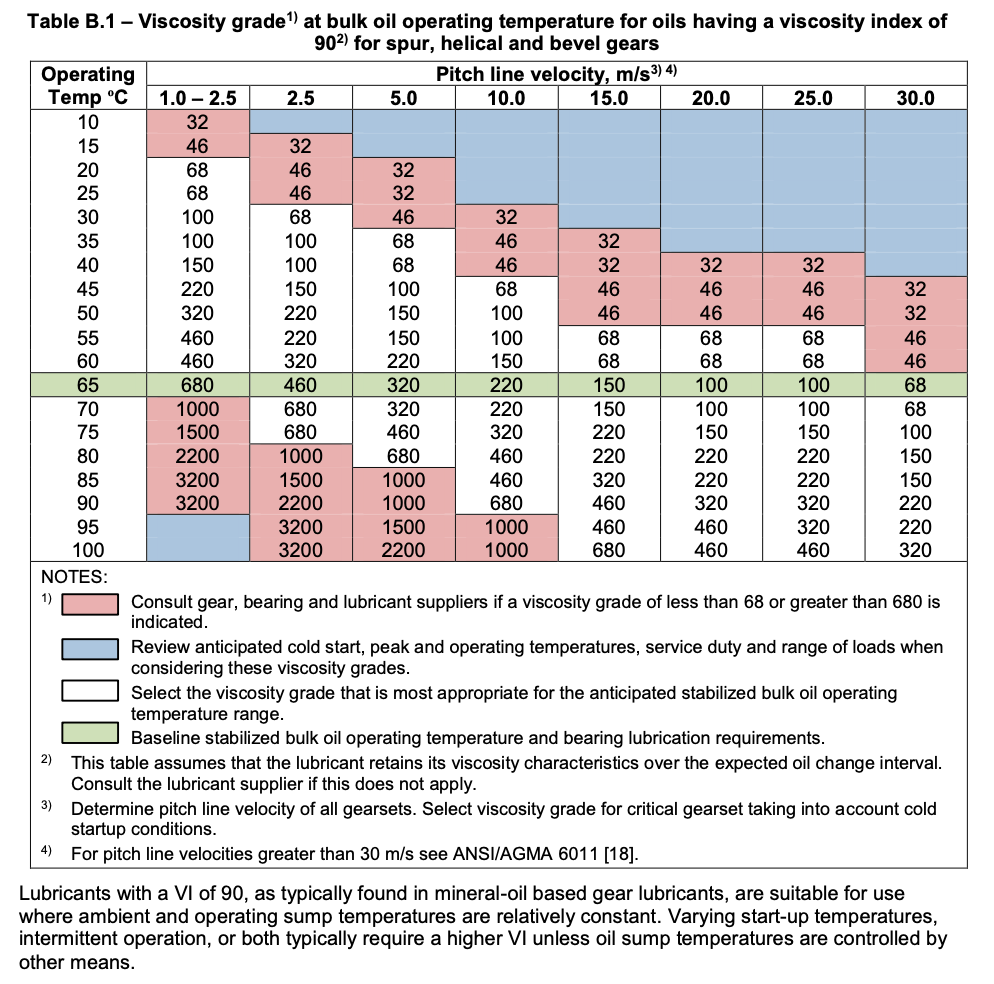

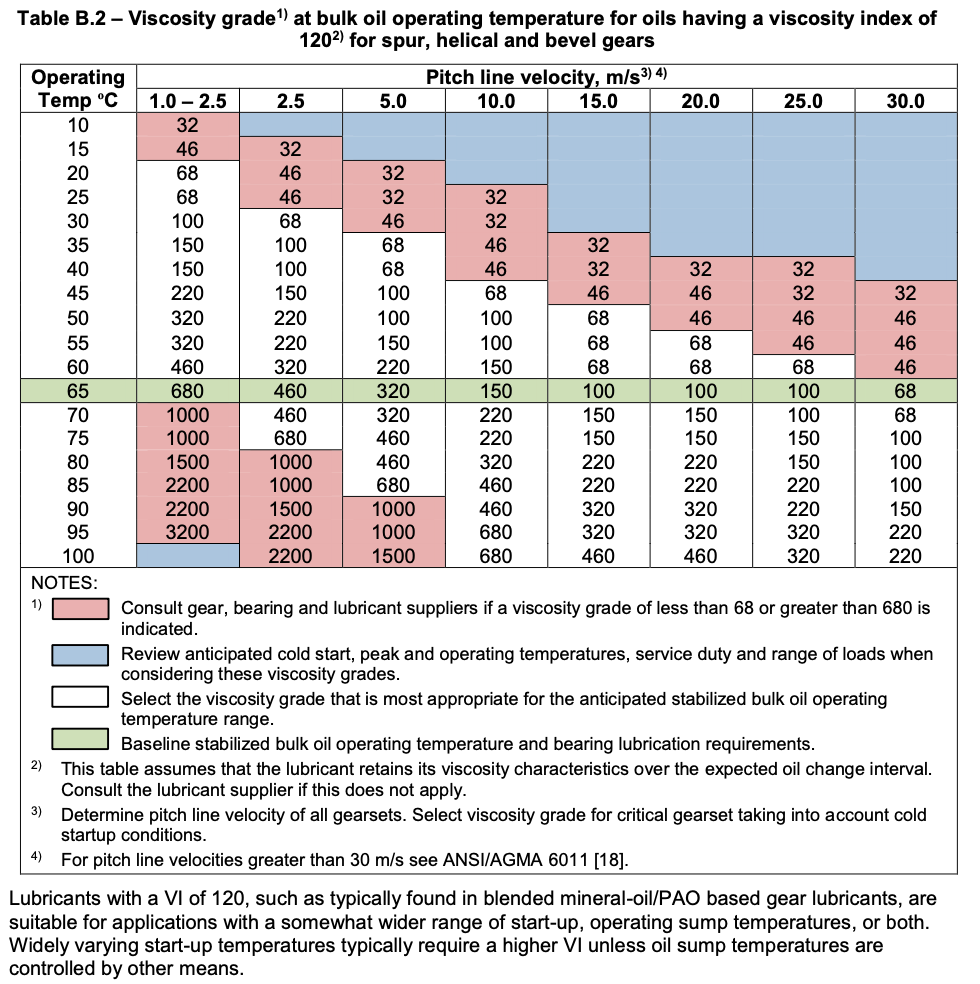

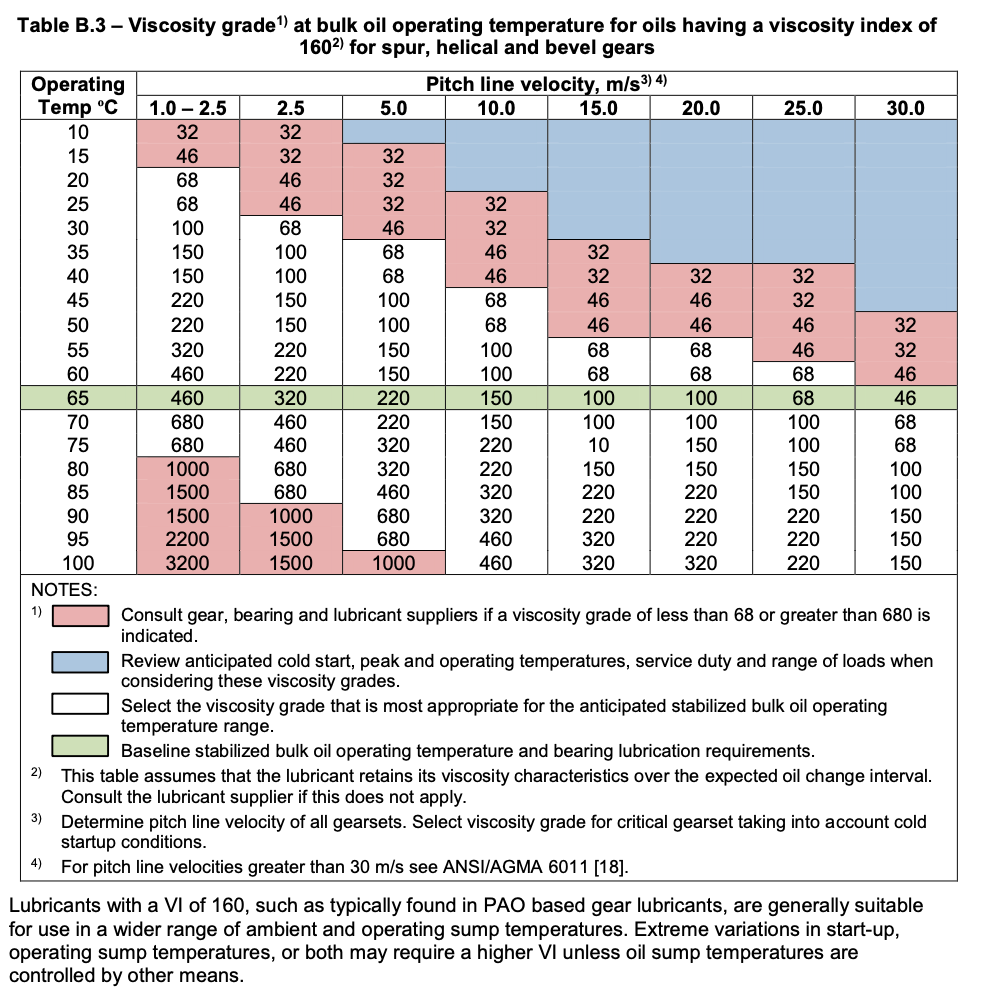

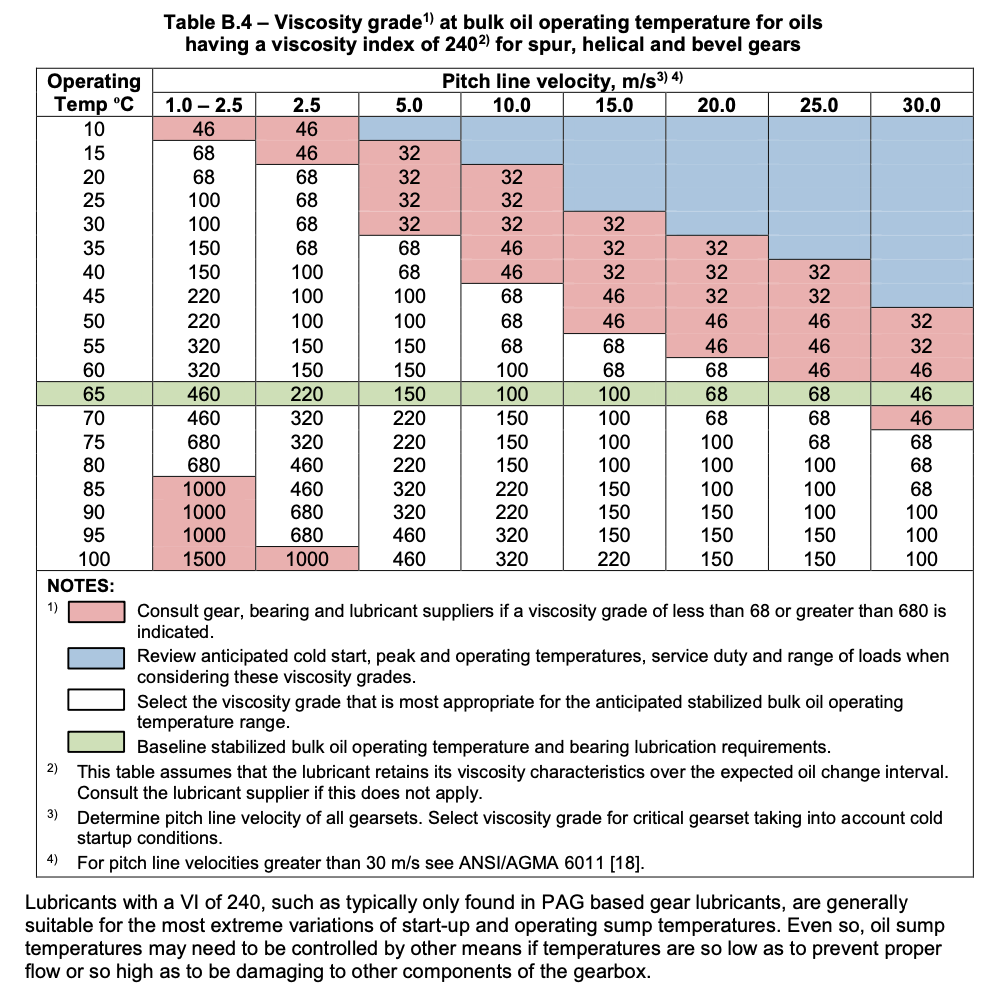

We need to match the oil to the process, so we'll look at the process first to determine what oil we need. Specifically, we need to know its operating temperature and pitch line velocity(or equivalent).

The operating temperature is just the temperature at which the machine will be operating, and pitch line velocity is the speed at which it's running. Now, pitch line velocity is a gear-specific term, but you can substitute the effective velocity for any moving equipment

Once we know what the process looks like, we can choose an oil based on its viscosity and viscosity index. The viscosity is a measure of how thick the oil is; high viscosity is thick like honey, low viscosity is thin like water. The viscosity gets thinner as it heats up, and the viscosity index determines how much the viscosity changes with temperature. A higher viscosity index means less change as it heats up or cools down, so if your equipment starts cold or runs hot, you'll need an oil with a higher viscosity index.

Our recommended process for determining which oil to use is:

1. Calculate the pitch line velocity (or equivalent) for your machine or operation

2. Determine the bounds of your operating temperature range (measure or estimate the hottest and coldest the machine will be)

3. Find where your process falls in the charts below, starting with the one for Viscosity Index of 90

4. If the chart has a recommend viscosity for your operating temperature and pitch line velocity, use that viscosity.

5. If the chart does not recommend a viscosity, look at the chart with the next higher Viscosity Index and repeat until you find a recommendation

6. The recommendation is the ISO VG grade, click here if you need to convert to a different standard.

7. If there are still no recommendations, consider looking at a grease or consulting your local lubricant suppliers.

At the end of the day, there are still many options for additives in oils. Your fancy machines might specify these in an owner's manual, but for the majority of everyday equipment, finding an appropriate viscosity and viscosity index is more than enough. And when it comes to older machinery, running an oil that isn't perfect is still orders of magnitude better than running dry.